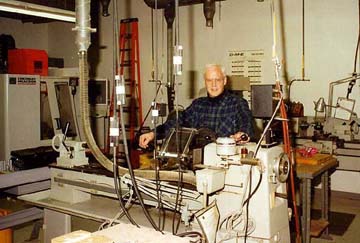

Programmable and manual machine tools.

Cincinnati Milacron's Arrow 500 (which is actually made in Great Britain) is a programmable 3-axis milling machine capable of extreme precision, handling cutters as small as .010", and respectable speed. The indexing head on the table inside the machine allows 4-axis work. The tool paths would be created in Surfcam, at my work station. The computer mounted on the machine can be used to make corrections on the fly. It uses Windows NT and has a touch-sensitive screen. I did all the lettering on my eyepieces with this machine. They may be more elaborate than is necessary, but it was fun!

Cincinnati Milacron's Arrow 500 (which is actually made in Great Britain) is a programmable 3-axis milling machine capable of extreme precision, handling cutters as small as .010", and respectable speed. The indexing head on the table inside the machine allows 4-axis work. The tool paths would be created in Surfcam, at my work station. The computer mounted on the machine can be used to make corrections on the fly. It uses Windows NT and has a touch-sensitive screen. I did all the lettering on my eyepieces with this machine. They may be more elaborate than is necessary, but it was fun!

You don't need a lathe like this one to build eyepieces. You don't even need a lathe--I have seen good working eyepieces made from plastic tubing, plumbing parts, and electricians tape. It just isn't that difficult!

You don't need a lathe like this one to build eyepieces. You don't even need a lathe--I have seen good working eyepieces made from plastic tubing, plumbing parts, and electricians tape. It just isn't that difficult!

Parts that you will make on a small lathe include: eyepiece lens holders, eyepiece barrels, objective lens cells, mounting rings, counterweights, eyepiece tube mountings, retaining rings, knobs, internal mount parts, adapter rings, and blank setting circles (do the indexing and numbers on your computer, print it out on clear or silver stock, and wrap the paper around the circles as shown on the 8-inch Newtonian on the reflector page).

For your basement workshop: There are a dozen of these small Unimat lathes on ebay every week. They accept a rod of stock up to 3 inches in diameter and about seven inches long. These lathes haven't been made in years, but they are still the best available. Every Unimat accessory ever made (and there are about a hundred) is also available on ebay. This is a typical case where an older machine is much higher quality than a newer one of the same type. The newer machines (especially the ones from China) are less expensive because Unimat (which was made in Austria) has held its value. It has the best reputaion of any small lathe ever made. Expect to pay about 300-400 dollars, depending on how many accessories you get with it.

For your basement workshop: There are a dozen of these small Unimat lathes on ebay every week. They accept a rod of stock up to 3 inches in diameter and about seven inches long. These lathes haven't been made in years, but they are still the best available. Every Unimat accessory ever made (and there are about a hundred) is also available on ebay. This is a typical case where an older machine is much higher quality than a newer one of the same type. The newer machines (especially the ones from China) are less expensive because Unimat (which was made in Austria) has held its value. It has the best reputaion of any small lathe ever made. Expect to pay about 300-400 dollars, depending on how many accessories you get with it.

There are now many, many small metal lathes like this 7 x 16 Micro-Mark available for less than $1000.00. They are all made in China, without exception, and they will all require some small amount of rebuilding to get them to work well. There are blogs all over the net on the pros and cons of these lathes, as well as instructions for improving them and sources where you can buy better tool rests and other parts to upgrade them. Start HERE to see what's happening in the mini-lathe world.